Why Magnetic Drive Pumps Are Essential for Malaysian Industries?

In Malaysia’s fast-growing industrial sector, efficiency and safety are two sides of the same coin. From chemical manufacturing plants in Selangor to water treatment facilities in Penang, the demand for equipment that performs reliably under harsh conditions is higher than ever. One key piece of technology that’s quietly transforming these operations is the magnetic drive pump.

For industries handling acids, solvents, or other corrosive liquids, even the smallest leak can result in major downtime, health risks, and costly cleanup. Magnetic drive pumps eliminate this concern with a sealless, leak-free design, helping Malaysian businesses protect both their workers and their bottom line.

Why Magnetic Drive Pumps Matter in Malaysian Industries

Industrial growth in Malaysia means more facilities are handling hazardous liquids daily. Regulations on environmental safety and worker protection are also becoming stricter. In this context, magnetic drive pumps are not just a choice—they are an investment in compliance, safety, and productivity.

Here’s why more Malaysian engineers are switching to magnetic drive pumps:

- Environmental Compliance: Prevent leaks that can cause contamination.

- Worker Safety: Reduce exposure to corrosive or toxic chemicals.

- Cost Control: Lower maintenance and replacement costs.

- Continuous Operation: With fewer moving parts, pumps run longer without failure.

Companies that prioritize these benefits are finding that the upfront investment in magnetic drive technology quickly pays off in reduced downtime and smoother operations.

Understanding Magnetic Drive Pump Technology

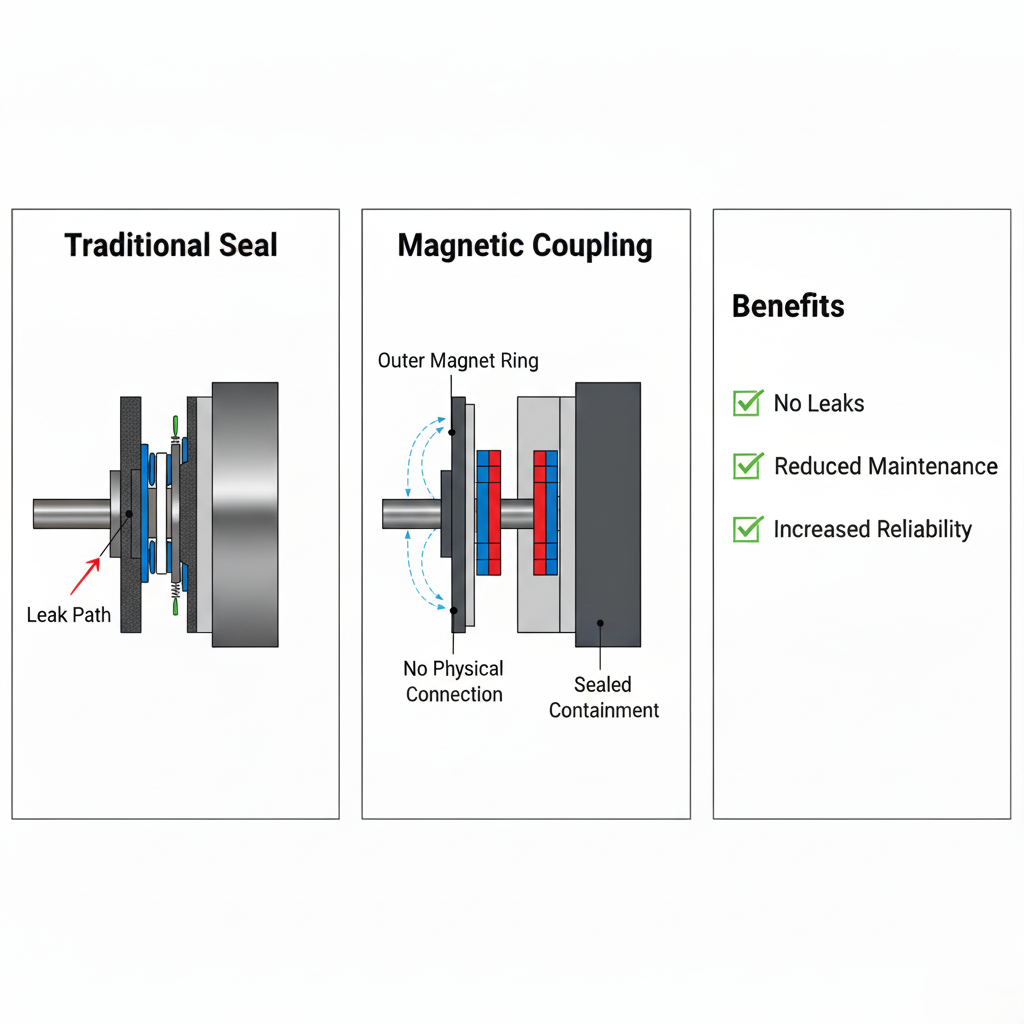

Unlike traditional centrifugal pumps that rely on mechanical seals, magnetic drive pumps use a magnetic coupling system to transfer energy. The motor’s magnetic field rotates the impeller through a sealed containment shell, creating motion without any direct contact between the motor and the pumped liquid.

By removing the need for seals, this design avoids one of the main causes of pump failure. It delivers longer service life, prevents leakage, and minimizes maintenance needs.

Key advantages of the design include:

- No Shaft Seals: Prevents fluid leaks, especially when pumping hazardous materials.

- Corrosion Resistance: Ideal for handling aggressive chemicals when built from materials like GFRPP or PVDF.

- Energy Efficiency: Reduced friction improves energy use over time.

For Malaysia’s chemical, plating, and water treatment sectors, these benefits translate to operational consistency and improved workplace safety.

Industry Applications

Magnetic drive pumps are now used across multiple Malaysian industries, proving their reliability in diverse environments.

| Industry | Typical Use | Key Benefit |

| Chemical Processing | Transfer of acids, alkalis, solvents | Leak-free, corrosion-resistant |

| Electroplating | Circulating plating solutions | Stable flow, no contamination |

| Water Treatment | Handling corrosive wastewater | Environmentally compliant |

| Food & Beverage | Moving cleaning chemicals safely | Reduces contamination risk |

| Pharmaceuticals | Sensitive or sterile liquid handling | Precision and reliability |

What to Consider When Choosing a Magnetic Drive Pump?

Before investing in a magnetic drive pump, it’s essential to evaluate a few practical factors to ensure long-term performance:

- Chemical Compatibility: Always confirm the pump’s materials match the type of liquid handled (e.g., GFRPP or PVDF for acids).

- Flow Rate and Head Requirements: Select a model that meets your system’s pressure and capacity needs.

- Operating Environment: Ensure the pump can handle your plant’s temperature and chemical conditions.

- Maintenance Accessibility: Even though magnetic drive pumps require less maintenance, easy part access improves service efficiency.

Taking these factors into account helps businesses choose a model that fits their needs and avoids premature wear or performance issues.

MP-120RM: Built for Reliable Performance

When it comes to finding a reliable magnetic drive pump in Malaysia, the MP-120RM Sealless Magnetic Drive Pump by Asia Pump stands out as a trusted choice. Built for demanding chemical applications, it delivers excellent performance, safety, and long-term durability.

Specifications:

- Maximum Flow Rate: 220 L/min

- Maximum Head: 10.5 meters

- Materials: GFRPP or PVDF

- Applications: Chemical transfer, plating, and wastewater treatment

Malaysian companies seeking a durable and dependable magnetic drive pump Malaysia can rely on the MP-120RM for consistent, leak-free operation. Its corrosion-resistant build ensures longevity, even in aggressive environments.

Conclusion

Magnetic drive pumps are more than just an upgrade; they’re a strategic investment in safer, cleaner, and more efficient industrial operations. For Malaysian industries involved in chemical processing, electroplating, or wastewater management, choosing the right pump can make all the difference in long-term performance and safety.

The MP-120RM Sealless Magnetic Drive Pump by Asia Pump reflects these values, combining durability, chemical resistance, and reliability to meet the demands of modern industrial environments.

FAQ about Magnetic drive pump

What makes magnetic drive pumps different from traditional centrifugal pumps?

Magnetic drive pumps use a magnetic coupling instead of mechanical seals, eliminating the risk of leakage. This design ensures safer operation, especially for handling corrosive or hazardous chemicals.

Why are magnetic drive pumps suitable for Malaysian industries?

Malaysia’s industries such as chemical processing, electroplating, and wastewater treatment are often handle aggressive fluids. Magnetic drive pumps provide reliable, leak-free solutions ideal for these demanding environments.

What are the main benefits of using a magnetic drive pump?

They offer leak-free performance, reduced maintenance, energy efficiency, and strong chemical resistance, making them a cost-effective long-term investment for industrial operations.

How do I choose the right magnetic drive pump for my application?

Consider factors such as flow rate, head, chemical compatibility, and temperature requirements. For accurate selection, consult pump specialists or review specifications like those of the MP-120RM Sealless Magnetic Drive Pump by Asia Pump.

Where can I buy a reliable magnetic drive pump in Malaysia?

You can find high-quality models such as the MP-120RM from Asia Pump, a trusted Malaysian supplier known for durable and chemical-resistant pump solutions.

Disclaimer:

We hope you find this article helpful and informative. Our content is intended for general informational purposes only and does not constitute advice or necessarily reflect the full range of services offered by Asia Pump (M) Sdn. Bhd.

For personalized advice, please consult with a professional or contact us directly. While we strive for accuracy and completeness in our blog posts, we cannot guarantee they are error-free. Asia Pump (M) Sdn. Bhd. assumes no responsibility for any errors or omissions.