Overview

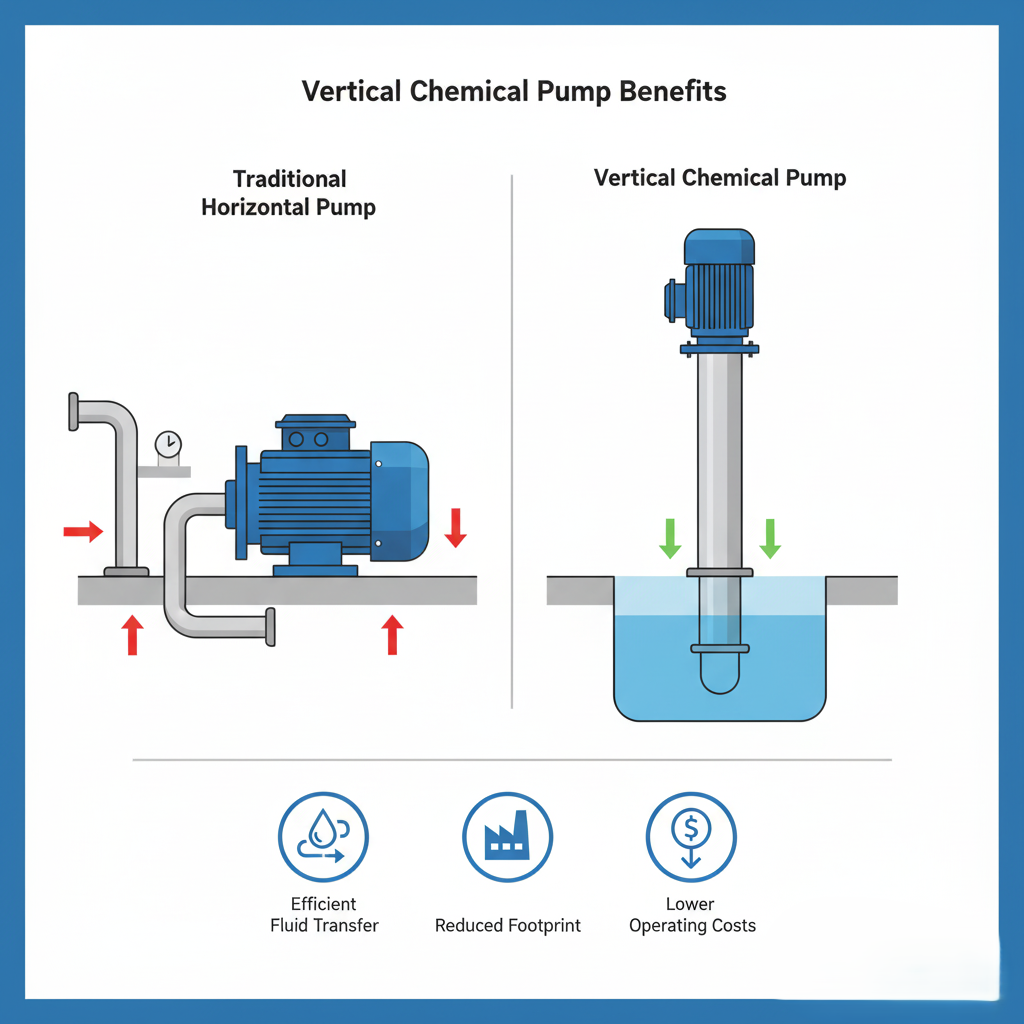

Selecting the right pump for your operation isn’t just about moving fluids, it’s about ensuring long-term reliability, safety, and cost efficiency. In many process industries, the debate often comes down to choosing between a vertical chemical pump and a horizontal pump.

While both have their uses, the vertical chemical pump has gained strong preference among engineers for its compact design, corrosion resistance, and superior safety in handling aggressive fluids. Let’s look deeper into how both pumps compare and why more facilities are switching to vertical designs.

Understanding the Difference between Vertical and Horizontal pump

A vertical chemical pump operates with its motor positioned above the liquid level. The pump shaft extends down into the fluid, keeping key components protected from direct contact with corrosive vapors or splashes.

A horizontal pump, on the other hand, is mounted at ground level, with both the motor and impeller positioned side by side. This design is common for water transfer, cooling systems, and other non-corrosive applications.

| Feature | Vertical Chemical Pump | Horizontal Pump | |

| Installation | Mounted above tank or pit | Installed on floor level | |

| Space Requirement | Compact footprint | Requires larger area | |

| Leakage Risk | Low – components above fluid | Higher – seals exposed | |

| Corrosion Resistance | Excellent | Moderate |

Benefits of Using Vertical Chemical Pumps

1. Space-Saving and Clean Installation

Vertical pumps are ideal when floor space is limited. Their upright design allows them to be mounted directly above tanks or pits, freeing up valuable workspace while reducing spill risks.

2. Superior Chemical Resistance

Built from high-grade materials such as PVDF, polypropylene, or stainless steel, vertical chemical pumps are engineered to handle acids, alkalis, and corrosive chemicals without compromising performance or safety.

3. Safer and Leak-Free Operation

With the motor and bearings positioned above the fluid surface, the vertical configuration minimizes exposure to harmful vapors and virtually eliminates leakage concerns — enhancing workplace safety.

4. Reliable and Energy Efficient

Vertical pumps deliver steady flow performance and maintain long service life, even in demanding environments. Their efficient hydraulic design reduces energy consumption and maintenance downtime.

Benefits of Using Horizontal Pumps

While vertical pumps shine in chemical applications, horizontal pumps also have clear strengths — especially for general and low-corrosion processes.

1. Easy Maintenance Access

All major components — the motor, bearings, and impeller — are mounted at ground level, making inspection and maintenance straightforward. This reduces service time and improves uptime.

2. Stable Operation for Clean Fluids

Horizontal pumps are perfect for non-corrosive or low-viscosity liquids, such as water or coolant, where the risk of leakage or chemical attack is low.

3. Lower Initial Investment

Horizontal pumps are generally more cost-effective upfront, making them a popular choice for facilities handling simple transfer processes or requiring large flow rates.

4. Wide Availability and Versatility

Because of their simple design and popularity, horizontal pumps are widely available, easy to replace, and can be used in many non-chemical applications.

Maintenance Tips for Both Types

Regardless of the type, a consistent maintenance schedule helps extend pump life.

Here are a few essential tips:

- Inspect visually before each use for leaks or vibration.

- Check seals and bearings regularly for wear.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Flush the system after handling chemicals to prevent buildup.

A short visual inspection before operation can prevent costly downtime and maintain reliable pump performance.

Why Vertical Pumps Are the Smarter Long-Term Investment

In industries where safety, chemical resistance, and space efficiency are top priorities, the vertical chemical pump consistently outperforms horizontal designs. While the initial cost may be slightly higher, the reduced maintenance, lower leakage risk, and improved operational safety make it a better long-term investment.

If your operation involves corrosive or hazardous fluids, choosing a vertical system isn’t just a preference, it’s a smart engineering decision.

Conclusion

Both vertical and horizontal pumps have valuable roles in industrial operations. But for processes involving corrosive, hazardous, or aggressive fluids, the vertical chemical pump remains the best long-term choice.

For professional guidance or to explore reliable vertical pump solutions, visit Asia Pump Sdn Bhd your trusted partner in industrial and chemical pumping systems.

FAQ about Vertical and Horizontal pump

Why are vertical chemical pumps better for corrosive fluids?

Their motor and bearings sit above the liquid, reducing contact with chemicals. Made from corrosion-resistant materials, they’re safer and longer-lasting in harsh conditions.

Can horizontal pumps handle chemicals too?

Yes, but they’re best for non-corrosive or mild liquids like water or coolant. For strong acids or solvents, vertical pumps are the safer choice.

How do I choose between vertical and horizontal pumps?

If you have limited space or work with corrosive fluids, go vertical. For simple, clean-fluid transfer and easier servicing, a horizontal pump works well.

Disclaimer:

We hope you find this article helpful and informative. Our content is intended for general informational purposes only and does not constitute advice or necessarily reflect the full range of services offered by Asia Pump (M) Sdn. Bhd.

For personalized advice, please consult with a professional or contact us directly. While we strive for accuracy and completeness in our blog posts, we cannot guarantee they are error-free. Asia Pump (M) Sdn. Bhd. assumes no responsibility for any errors or omissions.